Why You Need to Pay Attention to Vampire Energy

Vampire energy is what technical equipment uses when it’s not actively turned on. These devices still pull some level of power from the grid.

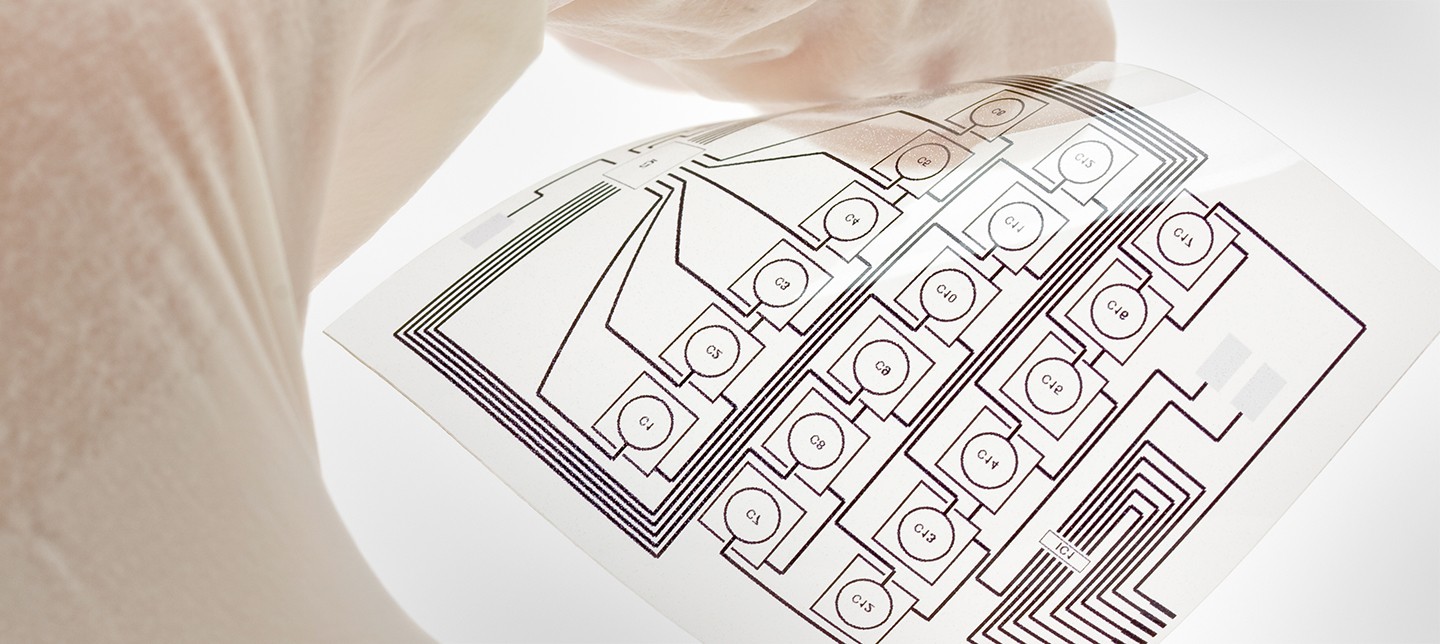

In the era of rapid technological evolution, flexible and wearable electronics are poised to reshape the way we interact with technology. The convergence of electronics and adaptability has sparked remarkable advancements. Flexible and wearable electronics challenge the very notion of what a device can be. With the advent of bendable displays and smart clothing, the boundaries of design, functionality, and integration are being pushed to new limits.

On one hand, bendable displays offer an exciting avenue for innovation, enabling devices to be curved, rolled, or folded without sacrificing visual quality. This breakthrough opens doors to unprecedented design freedom, transforming how we perceive screens and interact with information.

On another front, smart clothing marries technology with fashion, leading to a revolution in health monitoring and lifestyle enhancement. Imagine garments that monitor vital signs, adjust the temperature based on environmental conditions, or even generate power from body movement. These advances underscore the transformative potential of flexible and wearable electronics across industries as diverse as healthcare, entertainment, and fashion.

In the race to bring flexible and wearable electronics to market, time is of the essence. NI’s Power Performance Validation solution plays a pivotal role in decreasing time to market. By streamlining the product development cycle and expediting evaluation times, this solution indirectly addresses the power challenge. Its ability to quickly identify and resolve bugs not only accelerates the debugging process but also contributes to the development of more energy-efficient electronics. Engineers can finetune the device’s performance in real time, ensuring that power-hungry components are optimized and unnecessary energy consumption is minimized.

Moreover, the solution’s improved data management is aligned with power efficiency. The structured approach to handling the large amounts of data generated during validation prevents wasting computational resources, indirectly conserving power that would otherwise be used for data processing. As a result, NI’s Power Performance Validation solution facilitates efficient collaboration and informed decision-making, ultimately leading to quicker market entry.

Bendable displays, while revolutionary, face the challenge of mechanical durability. Electronic devices must withstand the rigors of daily use, and ensuring their resilience is imperative. NI’s Mechanical Component and Durability Test solutions help simplify what would otherwise be a complex testing process.

Traditionally, physical tests for mechanical components and product durability involved multiple sensor types, costly setups, and the construction of elaborate prototypes. NI’s approach disrupts this complexity by merging modular hardware with user-friendly data-logging software. This combination seamlessly guides engineers from sensor data collection to data analysis without requiring programming, minimizing effort and testing time.

The adaptability of NI’s mechanical test solutions means that the same software and core hardware components support an array of sensor modules, allowing for hassle-free sensor changes or additions. This flexibility not only expedites testing but also optimizes resource allocation, as engineers can build subsequent test systems without extensive investments in extra equipment.

In the dynamic landscape of technology, flexible and wearable electronics herald a new era of interaction and innovation. As bendable displays and smart clothing continue to redefine our technological journey, the importance of efficient validation cannot be overstated. Through these tools, the challenges of development and validation are transformed into opportunities for efficiency and advancement. NI’s solutions empower engineers and creators to navigate these challenges, shorten development cycles, and expedite market entry. The result is a future where technology is seamlessly integrated into our lives, enhancing our experiences and transforming the way we interact with the world around us.

Learn more about how a platform-based approach to electronics testing ensures you meet schedule, quality, and cost expectations when evaluating devices and components.